Pressure Exchanger

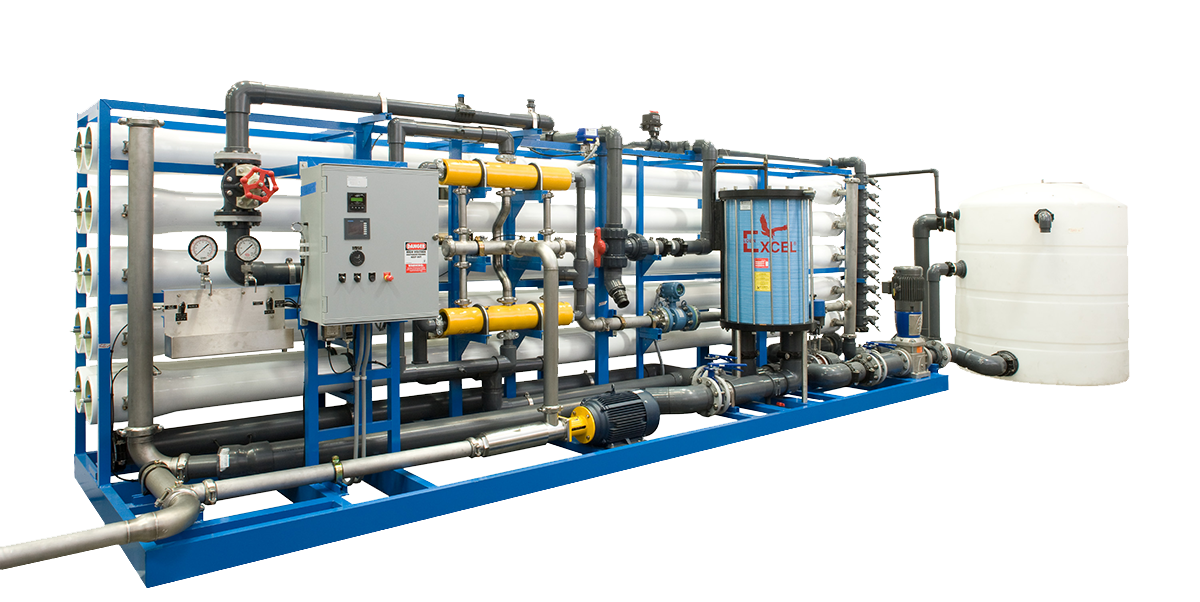

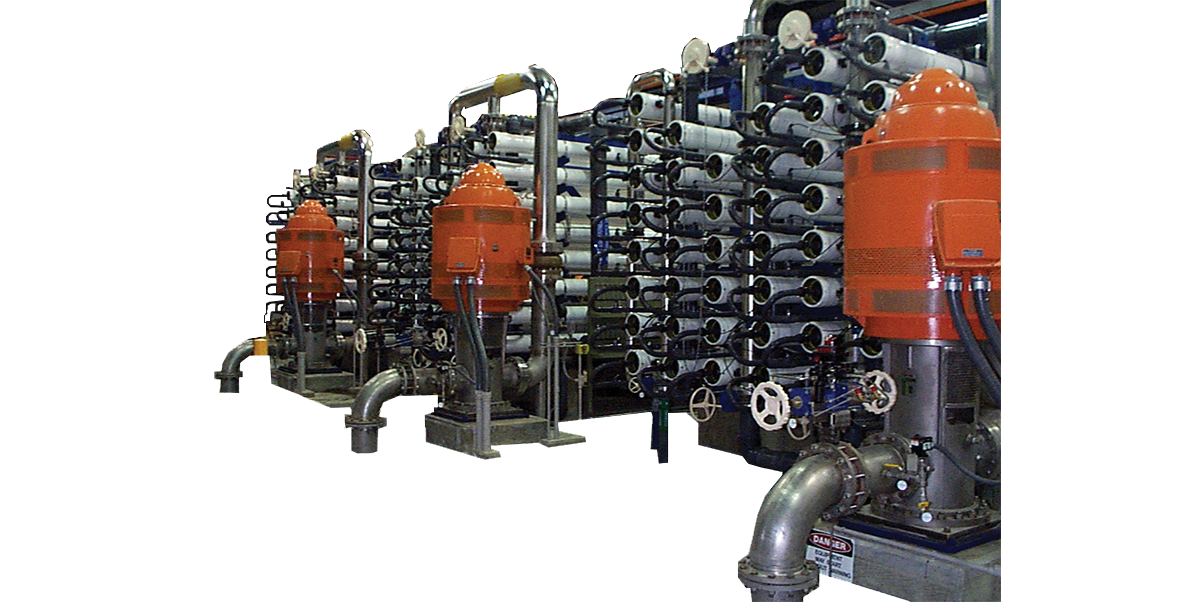

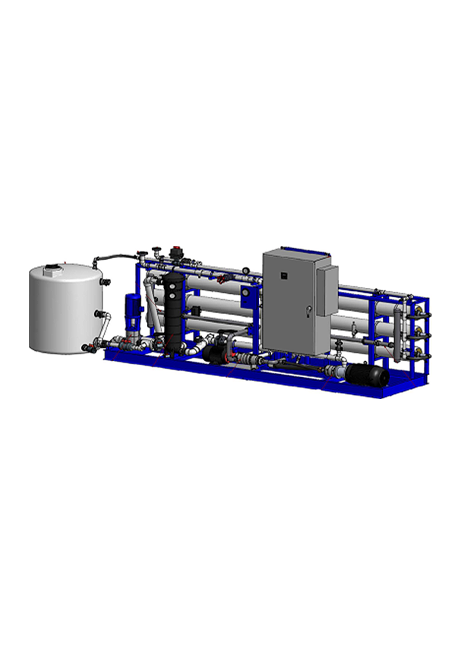

The SW series of RO systems, seawater desalination pressure exchanger are the perfect solution where energy costs are of greatest concern. The systems are a great fit for resorts, irrigation and drinking water applications that are in remote areas where energy costs are extremely high. The seawater desalination pressure exchanger will provide extra energy saving when it really matters. These systems are available with a broad range of options that will ensure a perfect fit for the user. A wide range of ancillary equipment is available to provide a complete system.

Standard Features

- Plumbed and integrated post shutdown product water flush system

- Variable frequency drive (VFD) for the high pressure pump

- Controlled by a PLC and touch screen human machine interface (HMI)

- Compact and skid mounted to minimize floor space and field installation

- Aircraft grade aluminum frame coated with marine grade polyurethane paint

- Integrated clean in place (CIP) system

- Easy serviceability. No hidden or out of the way components

- Five micron prefilter

- Premium efficiency positive displacement high pressure pump

- Multi stage booster pump *High efficiency pressure exchanger

- Multi stage centrifugal high pressure pump

- Skid mounted NEMA 4X low voltage control panel

- Stand alone NEMA 12 high voltage power panel (VFD enclosure)

- Schedule 10 super duplex high pressure piping

- Schedule 80 PVC low pressure piping

- Dry contacts for pre and post treatment equipment and tank level switches

Optional Features

- Multi-Media filters

- Pre-treatment and post-treatment chemical feed

- Feed pump and transfer pump stations

- SCADA system

- Containerized

Filters Coming Soon

Typical applications for this series includes:

- Hotel & Resort

- Municipal

- Industrial

- Offshore Platforms

- Military Facilities

- Remote Islands

- Irrigation

- Residential Seawater Communities

-

Features

- Plumbed and integrated post shutdown product water flush system

- Variable frequency drive (VFD) for the high pressure pump

- Controlled by a PLC and touch screen human machine interface (HMI)

- Compact and skid mounted to minimize floor space and field installation

- Aircraft grade aluminum frame coated with marine grade polyurethane paint

- Integrated clean in place (CIP) system

- Easy serviceability. No hidden or out of the way components

- Five micron prefilter

- Premium efficiency positive displacement high pressure pump

- Multi stage booster pump *High efficiency pressure exchanger

- Multi stage centrifugal high pressure pump

- Skid mounted NEMA 4X low voltage control panel

- Stand alone NEMA 12 high voltage power panel (VFD enclosure)

- Schedule 10 super duplex high pressure piping

- Schedule 80 PVC low pressure piping

- Dry contacts for pre and post treatment equipment and tank level switches

- Multi-Media filters

- Pre-treatment and post-treatment chemical feed

- Feed pump and transfer pump stations

- SCADA system

- Containerized

-

Request a Quote

-

Applications

- Hotel & Resort

- Municipal

- Industrial

- Offshore Platforms

- Military Facilities

- Remote Islands

- Irrigation

- Residential Seawater Communities

Specifications

Related products

-

SubMicron Filter

FC019A Flow Rate:3.5 GPMSize:9-3/4" x 2-3/4"Abs. Rating:0.4 MicronColor Code:Blue$295.00/1 Case(9 each)MOQ:1 Case

Flow Rate:3.5 GPMSize:9-3/4" x 2-3/4"Abs. Rating:0.4 MicronColor Code:Blue$295.00/1 Case(9 each)MOQ:1 CaseAbsolute rated filters, for the removal of bacteria, Giardia Cyst and chemical/solvent filtration.

Add to Cart -

Pre & Post Treatment

System

WET is able to provide a complete system from the feed water pumps to the distribution pumps and all things in between.

Learn More -

Custom Water

Treatment Solutions

We can provide complete, skid mounted packaged treatment systems for anything from advanced filtration systems for public water supplies to high purity systems.

Learn More -

Residential Reverse Osmosis

The 139BP models can produce up to 120 GPD, 0.45 m3/d of great tasting pure water. Includes models for both chlorinated (CAK) and non-chlorinated (NAK) water.

Select Options